The generally recognised technical rules and regulations of most European countries (in Germany, the relevant technical rules of the DVGW ) stipulate that a limit value of 0.2 FNU or 0.3 FNU must not be exceeded. An existing turbidity of the water considerably impairs the effectiveness of the disinfection. The same applies to ozone disinfection, which is increasingly being used. For this reason, filtration systems (rapid filtration) are often installed upstream of the respective disinfection stages during water treatment in order to reduce the particle load.

The monitoring of process turbidity in such filtration stages is usually continuous and requires sensitive and stable process measurement technology around the clock, as fast filters often provide very reliable measurement results with turbidity values well below 0.1 FNU.

The low-range process turbidimeters of the Lovibond® PTV 1000 series are ideally suited for this measuring task. The developers of this innovative instrument technology were able to draw on more than 20 years of experience in the technical conception, design, optical and application engineering of process opacifiers. As a result, Lovibond® can now offer a system that relieves the user of all the usual tasks. Worth mentioning here is the innovative, patent-protected, integrated air bubble separator and the much less frequent cleaning and inspection work. Another innovative feature is the ability to operate the instrument at very low flow rates and the use of T-CALplus calibration bags ("Formazin"), which ensure that rapid adjustment of the instruments can be performed without additional air bubbles and without user contact with the calibration solution.

Safety and reliability are just as important criteria for Lovibond® as efficiency in use and conservation of natural resources: the extremely low water consumption of the PTV process turbidimeters is unrivalled on the market.

The application spectrum of continuous turbidity measurement basically covers wide areas of water turbidity assessment. In water treatment, turbidity is also used on raw water or other untreated water with predominantly higher turbidity loads. Therefore, when monitoring a fitrate, devices are often found in practice that are only conditionally suitable for turbidity measurement at very low measured values, although their specifications sometimes promise a measuring range from 0 FNU (physically impossible as an absolute value) and often show clear measurement weaknesses or a lack of measurement dynamics for the detection and evaluation of temporary measured value changes at low turbidity values far below 1 FNU. However, this weakness is often considered tolerable as long as the measured values still tend to be in a safe value range below the required maximum turbidity according to the Drinking Water Ordinance (1 FNU). It should be noted that the PTV 1000 covers precisely this sensitive measuring range far below 0.5 NTU safely, reliably and dynamically for the above-mentioned applications.

In order to test the advantages of this new measuring instrument series in practice, the Lovibond® partner responsible for the Netherlands, , provided a PTV 1000 turbidimeter to a waterworks near Gouda. The measurement results from the PTV 1000 were compared with laboratory measurements and an already installed turbidity meter from another manufacturer. The meter was also evaluated in terms of ease of connection, maintenance and stability.

The meter requires only a low water inlet pressure, operates continuously open against atmospheric pressure (24/7) and then discharges the measured water via the outlet at time intervals of 20-30 sec. when the lowest flow rates (60-80 ml/min.) are set under flow control.

Since the water pressure at water supply were subject to greater fluctuations, a provided water column module was mounted for the PTV 1000. This made it possible to keep the flow through the unit and thus also the measured turbidity values very constant.

The unit was connected to a control room via the existing 0/4-20 mA analogue interface to display the trend curve.

The PTV 1000 can be configured and monitored via a touch screen or an app.

The practical test showed the following advantages of the PTV 1000:

- Very low water consumption - water savings of up to 4,200 litres per day !

- Reliable and extremely stable measurement

- Simple construction of the meter and easy disassembly of the measuring unit for service

- Maintenance-free/low maintenance, no cleaning required during the 3-month test period

- Easy readout and setting changes with associated app on a mobile phone or tablet

- Very good price/performance ration

Accuracy and stability of the measurement

During the test period, the measured values were also compared with the values measured in the laboratory. The results agreed very well. Any deviations were always within the previously defined tolerances.

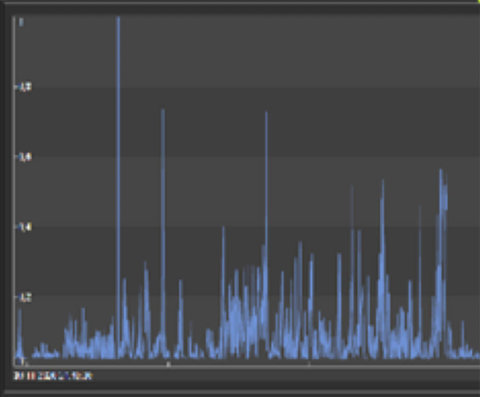

Old graph:fluctuating measured values.

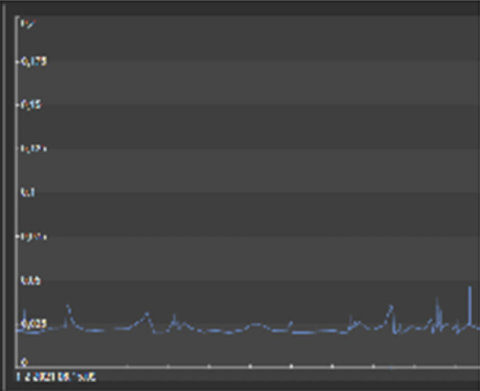

Graph of the PTV1000: very stable measured values.

The above graphs show the typical measurement process before and after the use of the PTV 1000.

While the results of the previous measuring device used for comparison in this test, starting from a basic value of 0.02 FNU, very clearly showed the previously known disturbances of a turbidity measurement ( fluctuation of measured values, e.g. due to air bubbles, pressure fluctuations, condensation, contamination, etc.), the measuring course of the PTV 1000 shows a clear improvement for the evaluation of measured values due to disturbance-free signal position with simultaneously given signal dynamics.

In addition to monitoring rapid filters, the PTV can also be used in related applications within drinking water treatment.

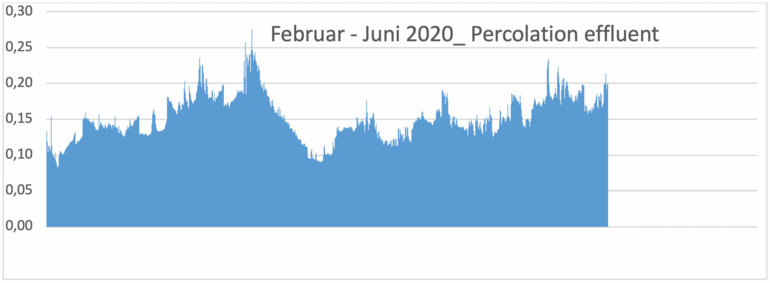

The figure below shows the typical course of a monitoring of filtrate from percolation, measured in spring/early summer 2020 in Germany.