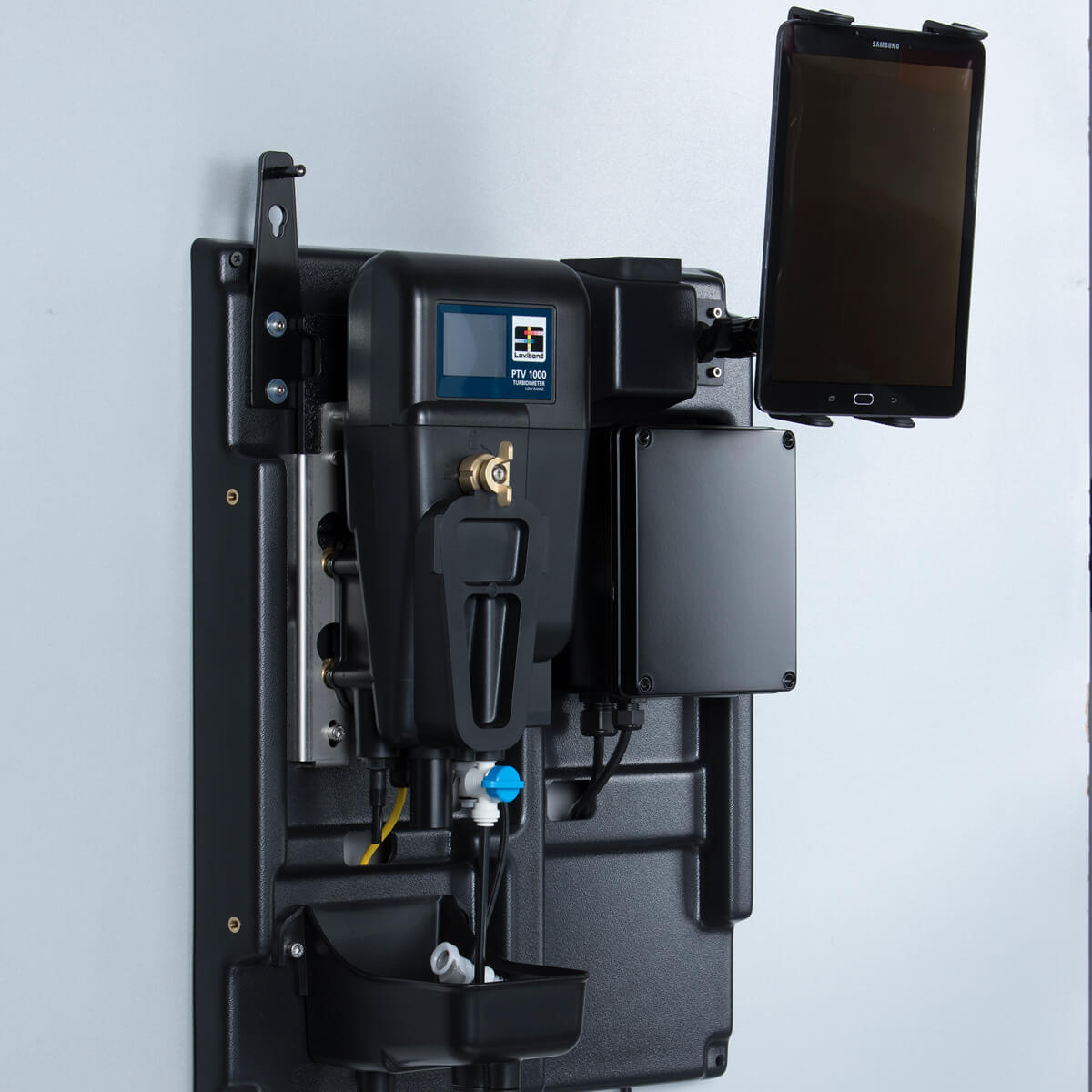

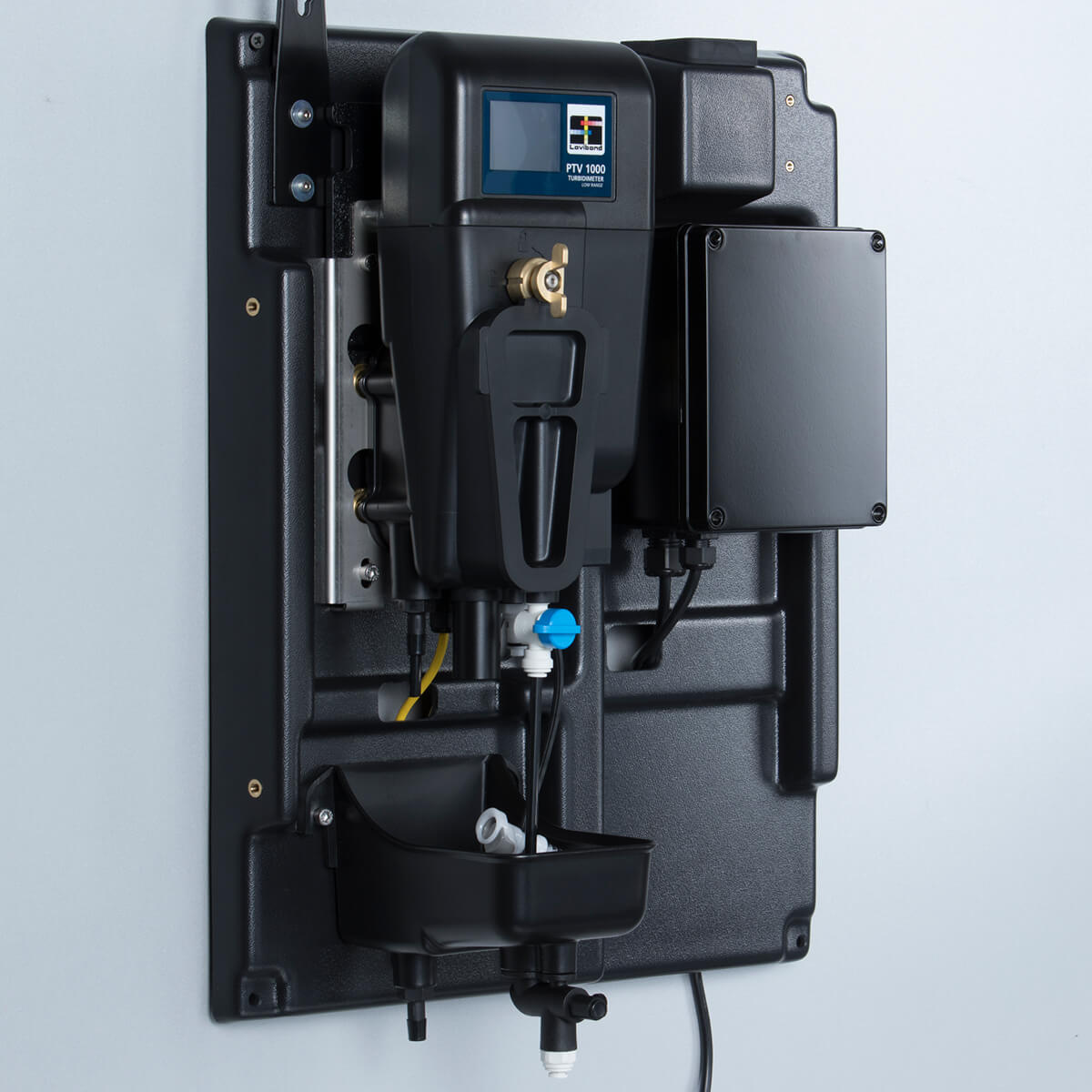

PTV1000 Process Turbidimeter with Flow Indicator; IR Light Source, ISO

With Flow Indicator; IR Light Source

- Online Turbidimeter for ISO 7027 compliance

- Touchscreen display eliminates need for a separate controller

- Integrated flow indicator ensures sample is flowing

- Optimized for grab sample comparison to laboratory instrument

The PTV1000 Process Turbidimeter is optimized for monitoring filter effluent in a regulatory environment. White Light and IR LED light sources are available.

The instruments are designed to consider every aspect of an operators’ work flow with an emphasis on simplicity and accuracy.

Part Number 6124683

Applications

- Drinking Water Treatment

Product information

-

See Changes Fast

In filter effluent turbidity measurement, slight changes in turbidity can be used to optimize the performance of the filter and potentially the treatment process upstream. The small volume flow body combined with our optical system helps operators see changes in turbidity quickly allowing them to react to changes in their process efficiently. -

Simplified Workflows

In low level turbidity monitoring, small differences in how key processes are performed can lead to a big difference in results. In order to help operators, work efficiently and consistently, all PTV Series instruments walk the user through key processes like calibration and verification. -

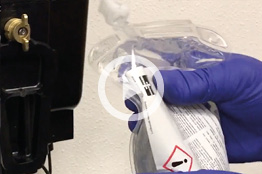

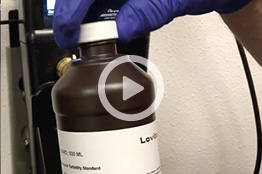

Easy Calibration & Verification

Lovibond® T-CALplus ® standards are primary standards that meet US EPA and ISO requirements for calibration. This self-contained system allows operators to follow best practice techniques, without coming into contact with formazin solution. Standards are available in a variety of concentrations to meet routine calibration and verification requirements. -

Save Water

Stop throwing finished water away! The optimal flow rate of the PTV Series is 40 - 120 ml per minute, while many other competitive instruments require 500 ml per minute or more. This difference in required flow rates translates to over 1 million gallons of finished water saved over the life of a single instrument, without compromising on the limit of detection or accuracy. -

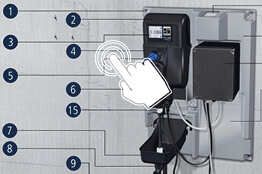

Rethink the Controller

Every PTV Series instrument has an integrated touchscreen display, so there is no need to install a separate controller. Information relevant to daily controls and processes are always clearly displayed on the screen. With the optional Bluetooth® feature, operators get access to our AquaLXP app, which is an enhanced version of the touchscreen with tech tips and animated instructions.

| Optics | Infrared light |

| Accuracy | ± 2 % of reading from 0 to 10 NTU ± 4 % of reading between 10 to 100 NTU |

| Display | Touchscreen |

| Stray Light | smaller 0.005 / 5 mNTU |

| Displayed Resolution | up to 0.0001 NTU (range dependent) or 5 digits displayed |

| Repeatability / Precision | better than 1% at 1 NTU |

| Initial Response | 10 % change: 15 seconds @ max flow |

| Step Response | (T-90), less than 240 seconds at 200 ml/min. at 1 NTU |

| Signal Averaging | User Selectable: 1, 3, 6, 10, 30, 60, and 90 seconds, defaulted to 30 seconds |

| Sample Temperature | 0 - 50 °C (32 to 122 °F) max sample temperature: 70 °C (158 °F) |

| Sample Flow | 30 to 500 ml/min, optimal flow: 50 to 80 ml/min |

| Sample Inlet Connection | 1/4-inch NPT female, 1/4-inch compression fitting tubing (included) |

| Sample Outlet (Drain) Connection | 3/8-inch NPT female, 3/8-inch hose barb tubing (included) |

| Power Requirements | 90 to 264 VAC, 50/60 Hz. Auto Select |

| Sample Inlet Tubing | 1/4-inch OD or 6 mm OD |

| Sample Oulet Tubing | 3/8-inch OD or 9 mm OD |

| Turbidimeter Body Drain | Quick connect with integrated check valve |

| Calibration | One Point Calibration at 5.0 or 20 NTU with any regulatory approved formazin |

| Analog Output: Measurement Module | 1 selectable 0 - 20 mA or 4 - 20 mA; output span programmable over any portion of the measurement range |

| Analog Output: Junction Box | 1 selectable 0 - 20 mA or 4 - 20 mA; output span programmable over any portion of the measurement range |

| Alarms | Three set-point alarms, each equipped with an SPDT relay with unpowered contacts rated 5 A resistive load at 230 V, AC |

| Digital protocol | 4-20 mA |

| Enclosure Type: Junction Box | Fiber reinforced polyester |

| Enclosure Rating: Junction Box | IP 66 |

| Safety | Listed by TÜV Rheinland to UL 61010A-1: Certified by TÜV Rheinland to CSAC22.2 No. 1010.1: CE Certified by TÜV Rheinland to EN 61010-1 |

| Immunity | CE certified by TÜV Rheinland to EN 61326 (Industrial Levels) |

| Mounting Hardware | Turbidimeter Sensor - Slotted Mounting Bracket that can be affixed to any vertical surface or panel (Optional). Junction Box - Direct mounting to any vertical surface or panel (Optional) |

| Method of Verification | Wet Standards or dry verification device |

| Limit of Determination | 0.0005 NTU |

| Limit of Detection | 0.005 NTU |

| Flow Indicator | yes |

| Portability | Process |

| Environmental Conditions | 5 - 50 °C, rel. humidity 5 - 95 % (Non-condensing) |

| Stock Conditions | -40 - 60 °C (-40 - 140 °F) |

| Compliance | ISO 7027 |

| Dimensions | 158.4 x 340.4 x 334.5 mm |

| Testparameter | Measuring Range | Method No. | |

|---|---|---|---|

| Turbidity | 0.0001 - 100 NTU |